- Jira Service Management + Assets digitize maintenance and servicing centrally and transparently.

- Automatic maintenance tickets replace manual schedule upkeep and prevent forgotten intervals.

- Faults are reported directly via the portal – clear paths, faster response, less downtime.

- A knowledge base in Confluence retains knowledge within the company and reduces follow-up questions.

- Dashboards show maintenance history & bottlenecks and make processes more predictable.

Industry to me means not only efficiency, productivity, and competitiveness — above all it means machines that must run reliably. My own experience in workshops and mechanical engineering has shown me how much depends on functioning workflows: As soon as a machine stands still, minutes quickly turn into hard cash, and improvisation is rarely the best solution.

That makes a solid maintenance process all the more important. Yet many operations still run into the same problems: documentation on paper slips or scattered Excel spreadsheets, information duplicated, and a lack of transparency. The result: high time expenditure, unnecessary errors, and, in the worst case, costly downtime.

This is exactly where Jira Service Management, together with Assets (CMDB) and a knowledge base in Confluence, delivers real value. Maintenance cycles, incident reports, and service requests can be mapped digitally, transparently, and sustainably. From automatically generated tickets to complete documentation, you get maintenance management that is not only efficient but also supports the entire production operation.

Maintenance as a process – typical challenges

Let’s take a look at the challenges we face in maintenance and repair:

- Manual management of maintenance intervals

- Machine incidents reach maintenance with a delay

- No central view of maintenance and action history

- Knowledge resides only with the responsible individuals, not within the company

This is where we leverage the powerful combination of Jira Service Management and Confluence: Instead of scattered data with individuals and greasy notes stuck to machines, there is a clearly structured knowledge base and automatically distributed tasks. More predictable, efficient, and less error-prone.

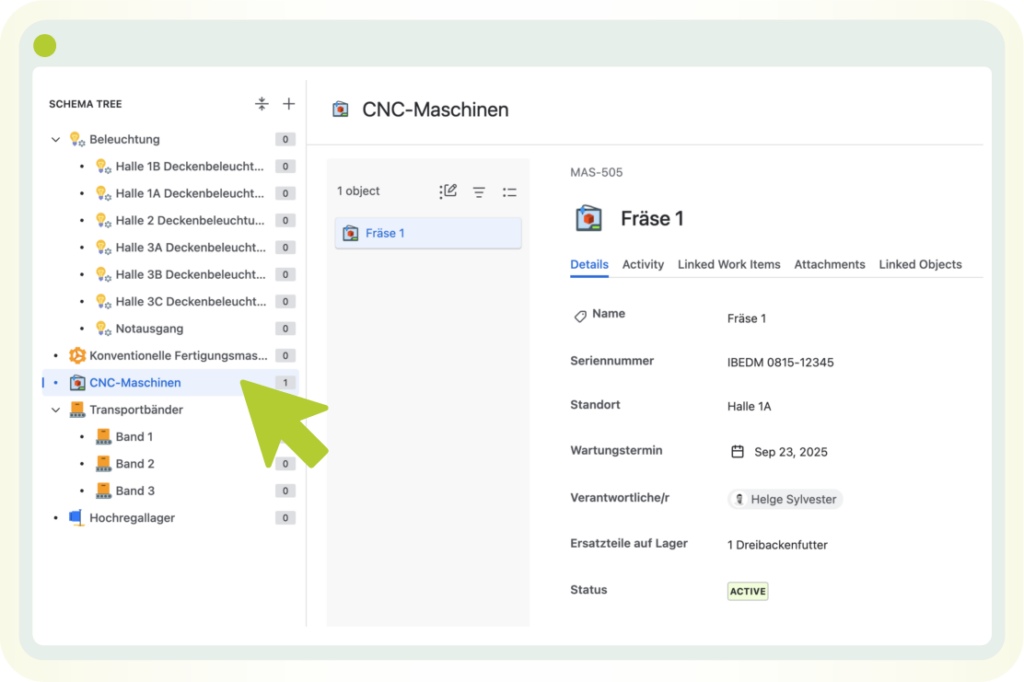

Step 1: Map production assets in Assets

The basis for good, modern maintenance management is the digital representation of your production assets. With Assets it becomes possible to record all machines, equipment, tools, and spare parts in a structured way. We can even model their relationships and track status.

Examples of attributes for individual assets:

- Machine ID / serial number

- Location

- Maintenance interval (e.g., top up oil every three months or replace a V-belt after 1,000 operating hours)

- Responsible technician

- Spare parts installed / in stock

- Machine status

- Relationship to other manufacturing steps

The big advantage is defining the attributes once for all machines and then maintaining them individually. This way, we always have all relevant facts for each object in the database at a glance.

Step 2: Generate maintenance tickets automatically

Instead of relying on manual upkeep and checking of maintenance intervals, in this example we can rely entirely on the assets we just set up.

Here’s what that can look like:

- Create an automation rule or script: “When the maintenance due date of an object is reached → Create a new maintenance ticket.”

- Example workflow:

- A ticket is created with a reference to the object (e.g., milling machine #1).

- The responsible technician is automatically set as assignee.

- The SLA starts automatically for tracking purposes.

![]() Here we have all information at a glance and can even document and communicate directly via comments. Compared with the combination of Excel lists and greasy notes on the machine, this is a real and effective step forward!

Here we have all information at a glance and can even document and communicate directly via comments. Compared with the combination of Excel lists and greasy notes on the machine, this is a real and effective step forward!

This ensures that technicians are prompted to service the machines at the desired intervals. Clean, reliable, and without anyone having to maintain schedules manually.

Step 3: Report machine faults directly in the JSM portal

Of course, machine reliability doesn’t depend only on the maintenance plan. Spontaneous events — like a snapped belt or a defective motor — can also cause production stops. With Jira Service Management, the operators at the machines can easily report a fault in the portal.

- Employees select the relevant asset in the portal (e.g., a machine or a defective tool).

- Required fields ensure the responsible team receives all the information it needs.

- Because responsibility is stored, the relevant technicians are notified directly.

The result is short paths for fault reporting, no emails that get lost in inboxes, and no walks to the workshop only to find that the responsible technician is currently busy elsewhere. It becomes particularly exciting when machines themselves are connected to the IT infrastructure and can automatically report irregularities via tickets!

Step 4: Knowledge base for technicians and employees

A machine fault doesn’t always have to result in a ticket. Often it’s minor issues that an operator can resolve themselves. To support this with documentation, Jira Service Management comes with a knowledge base:

- Known errors can be described in detail in articles.

- Step-by-step guides with images or videos reduce follow-up questions.

- During ticket creation in the portal, relevant articles are automatically suggested for the potential issue.

- Documentation such as operating manuals or spare parts lists can be stored centrally.

Step 5: Transparency through dashboards and reports

One of Jira’s major advantages is reporting. In dashboards and reports, we can visualize the failure tendency of individual machines or the on-time adherence to maintenance plans. This makes it easy to filter out processing bottlenecks or machines that are particularly prone to faults. It becomes easy to spot trends and initiate necessary measures.

Maintenance of a production machine as a practical example

In Assets, a machine is recorded, “Laser Cutter 7500,” with a maintenance interval of three months. Because the interval is defined, we also have a date by which the maintenance must be completed. This is where our automation comes in: Seven days before the due date, a ticket is created automatically — with all relevant data and work orders needed for this maintenance.

The responsible people are notified automatically and can schedule the maintenance in good time. Thanks to the extensive entries in Assets, staff see as soon as they open the ticket that all wear parts are in stock — so nothing can go wrong. After the maintenance is completed, a report including any anomalies is documented and stored in the knowledge base. This makes it traceable what happened, and the quick-help for machine operators remains meaningful and always up to date.

Benefits for industrial companies

- Predictability: Maintenance cannot be forgotten.

- Responsiveness: Faults can be reported directly to the right contacts — without detours or empty workshops.

- Transparency: Machines, maintenance, spare parts, and maintenance reports can be viewed centrally in one place.

- Knowledge management: Know-how is captured by the company and doesn’t remain only in the heads of individuals.

- Compliance: Well-maintained machine documentation is required for many certifications — and is now always fully up to date.

Conclusion

A structured maintenance and repair management system is more than just a duty — it is a competitive advantage. With Jira Service Management, Assets, and a knowledge base in Confluence, processes can be made predictable, transparent, and future-proof. This not only keeps operations running smoothly but also ensures that knowledge stays within the company rather than with individuals.

As someone who has personally experienced how expensive downtime can become, one thing is important to me: digitalization must be tangible, not theoretical. Jira provides the tools that truly ease everyday work — from automatically created tickets to clear documentation.

My goal is to find solutions that really work in day-to-day operations. If you want to take your maintenance and repair to the next level, just contact me — I look forward to the conversation.